Oribay Group Automotive

Driving innovation in auto glass and beyond

With over 30 years of experience in the automotive glass industry, we work closely with leading glass makers and car manufacturers to create new solutions that help shape the future of driving.

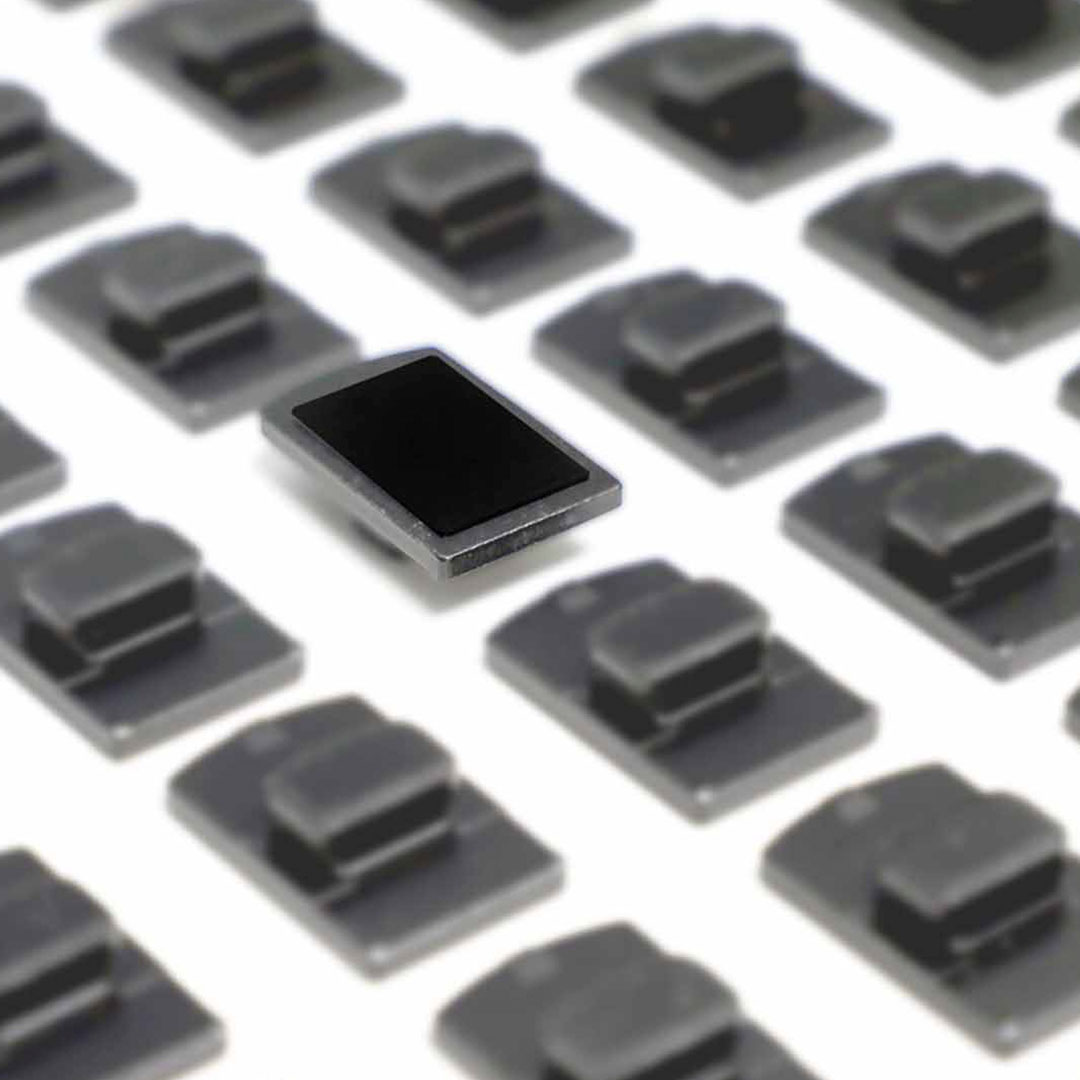

Our journey began in the late 1980s when the mirror button was introduced, a solution that changed the way rearview mirrors are mounted in cars. This innovation allowed mirrors to be attached directly to the windshield instead of the roof. Since then, we have continued to innovate with products like ADAS camera brackets, rain and defog sensor mounts, structural adhesives, glass coatings, and windshield electronics.

30+ Years of commitment

For decades, we have partnered with leading companies to provide innovative solutions, supporting their success and driving the future of mobility

1993

Foundation

Oribay is founded in San Sebastian, Spain, where it begins working on the development of windshield parts. At the same time, the company secures its first OEM project with a major European vehicle manufacturer.

1996

Oribay France

1998

Oribay China

2007

Oribay Japan

2010

SBT Adhesive Launch

2014

Sintering Plant

We open a new sintering plant in San Sebastian, Spain, dedicated to producing complex windshield components in stainless steel and carbon steel. With this expansion, our production capacity reaches millions of parts per year.

2015

Plastic & Metal Plant

With rising demand for plastic windshield components like camera brackets, we acquire AZU in Pamplona, adding capabilities in plastic, zinc, and aluminum injection, plus sheet metal stamping. In 2017, we acquire Talleres Mendaza.

2016

Electronics Plant

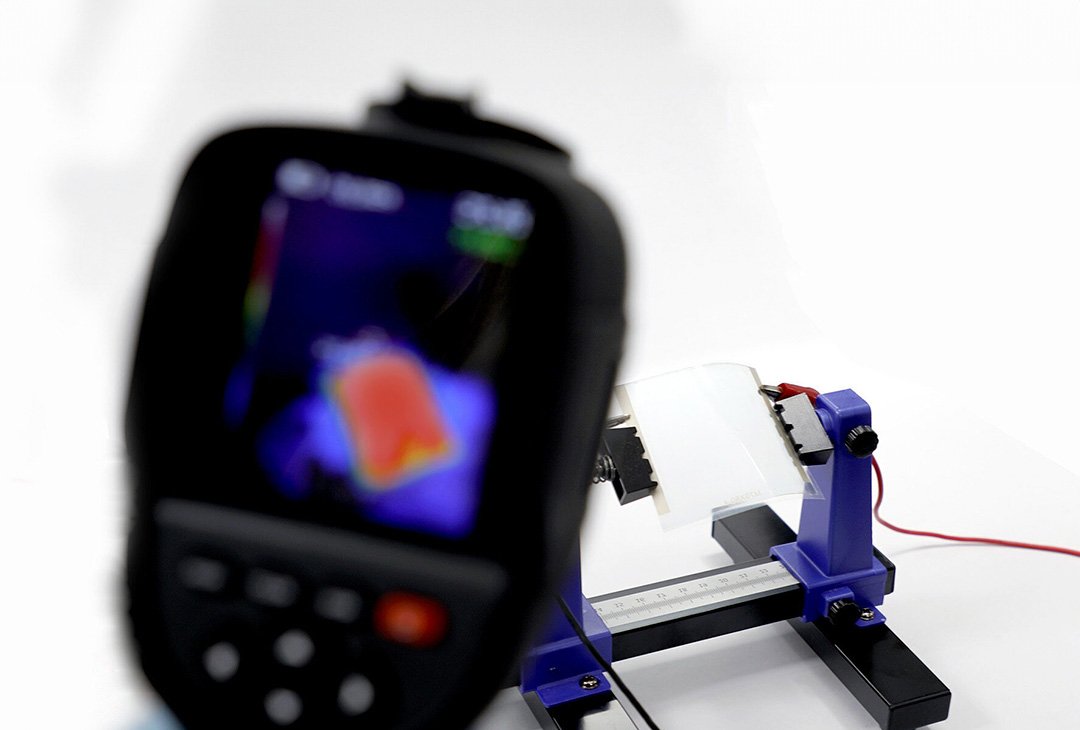

In 2016, we inaugurate a new electronics plant at our San Sebastian headquarters, expanding our capabilities to manufacture advanced windshield components such as camera heaters, defog sensors, and optics.

2019

Masermic Electronics

2020

Kronowetter Gmbh

In 2020, Kronowetter Gmbh joined the Oribay Group, bringing advanced expertise in component manufacturing with smart plastics, MIM, and silicones, while strengthening connections with German OEMs.

2024

North America & AGR+

After years of on-the-ground sales and engineering, Oribay Group America Inc. was established in Michigan, USA, alongside the launch of AGR+, a new product range for glass fitting workshops. We also opened a new facility in the Dominican Republic.

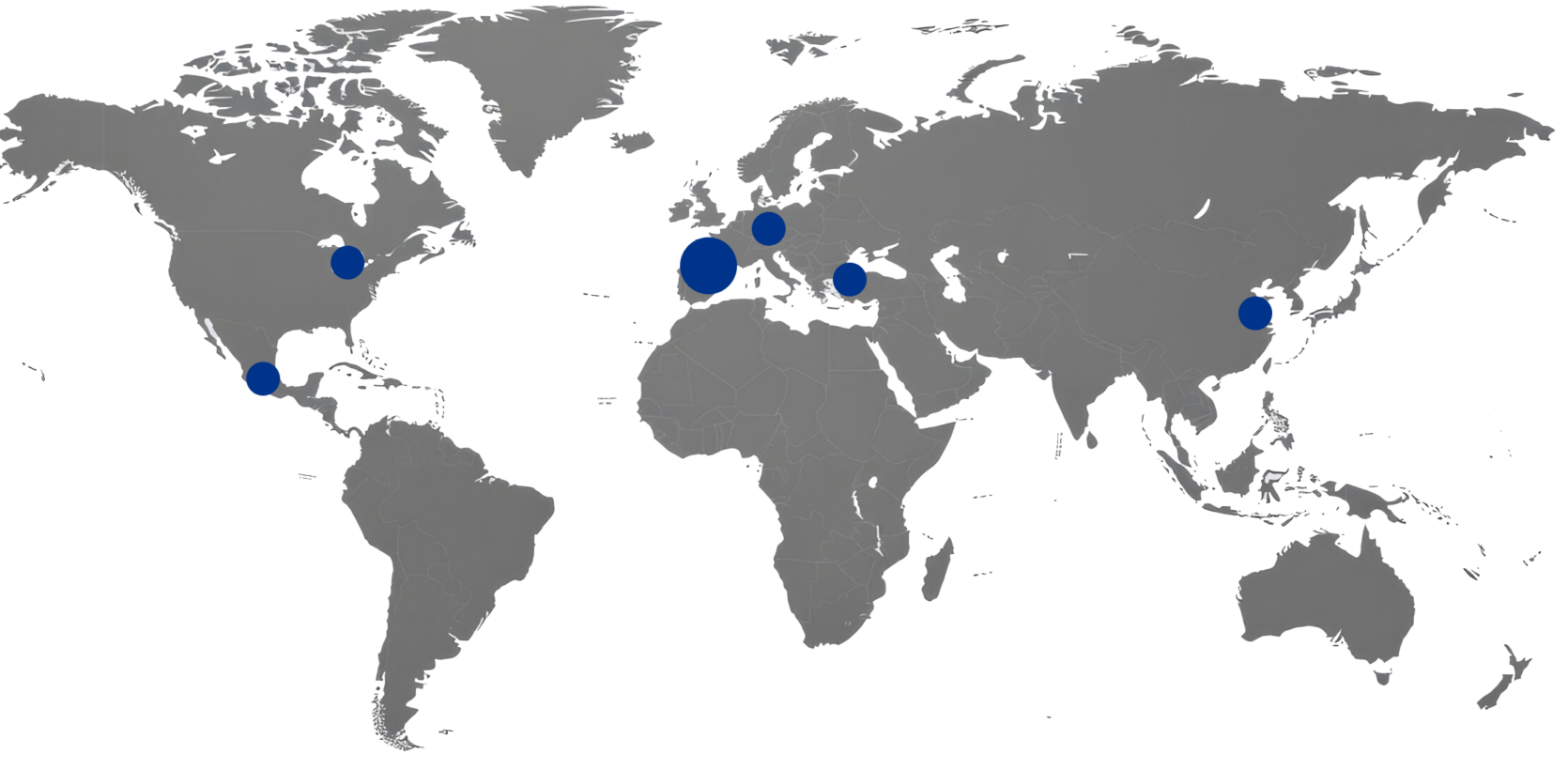

Worldwide network

We design and manufacture advanced solutions for the auto glass industry, trusted by the world’s leading windshield manufacturers. Our global presence allows us to address challenges effectively, offering high-quality support through our dedicated sales network.

Our headquarters and main production facilities are in San Sebastian (Spain), with additional plants in Pamplona (Spain) and Bavaria (Germany). We also have sales offices in Michigan (USA), Mexico, Turkey, and a newly opened office and warehouse in China.

Our Mission, Vision & Values

Learn more about our commitment to excellence, innovation, and ethical values

Our Mission

Our mission is to design, manufacture, and supply innovative, safe, and sustainable solutions for the automotive industry. We are dedicated to driving progress through cutting-edge technology while ensuring the highest standards of safety and environmental responsibility.

Our Vision

Our vision is to transform science and technology into groundbreaking solutions that go beyond our core automotive glass components, expanding into new industries. We aim to drive innovation and create impactful advancements that shape the future of various sectors.

Our Core Values

Commitment.

Willingness to give the best of oneself in every project within the company.

Respect. Recognition and consideration of others as equals.

Excellence. Pursuit and development of best practices in all areas of Oribay's activity, always guided by efficiency and economic responsibility.

Transparency. Clarity and openness in both internal and external communication across the organization.

Team Spirit. Working with a collective mindset—being supportive, sharing, complementing each other, and making the most of the opportunities our diversity offers.

Enjoyment. A positive outlook on daily work and the environment, both in moments of success and during challenges.

Innovation and Learning. Creating an environment of continuous individual and collective learning and collaboration, encouraging initiative to generate ideas and turn them into reality, building competitive advantages.

Corporate Social Responsibility (CSR)

At Oribay Group Automotive, we understand that business success is closely linked to our impact on society and the environment. For this reason, we are committed to Corporate Social Responsibility (CSR) as an essential part of our strategy. Our commitment to CSR not only strengthens our mission to create value but also enables us to actively contribute to collective well-being and the sustainable development of the automotive industry.

- Reducing our environmental impact with sustainable practices

- Creating an inclusive, fair, and safe workplace

- Supporting community development through social projects

- Acting with transparency and ethics in everything we do

Inclusive, Equitable, and Safe Workplace

At Oribay, we are committed to creating a workplace where people thrive. By prioritizing safety, equality, diversity, and respect for human rights, we aim to build an environment that supports personal and professional growth while reflecting our values of responsibility, integrity, and sustainable success.

- Safe Environment: We adhere to the highest standards of workplace safety and health, as certified by ISO 45001:2023. This ensures that our employees work in a risk-free environment where their well-being is a top priority. We proactively identify and mitigate potential hazards, provide regular training, and continuously improve safety measures to create a culture of health and protection. Employee feedback is essential in this process, as it helps us stay vigilant and adaptable to evolving needs.

Equality and Diversity: Our Equality Plan is the cornerstone of our efforts to build a culture that values and respects differences. We actively promote equal opportunities and create policies that eliminate discrimination based on gender, age, origin, or condition. By encouraging diversity, we unlock the full potential of our workforce, fostering innovation, creativity, and mutual respect. From fair hiring practices to ongoing professional development programs, we ensure everyone has the resources and opportunities they need to succeed.

-

Ethics and Transparency: Integrity is at the core of everything we do. We operate with transparency in all our business practices, fostering trust among employees, clients, and stakeholders. Our commitment to ethics extends beyond compliance; it is a guiding principle in how we make decisions, conduct operations, and build partnerships. We also uphold the highest standards of human rights, ensuring that our actions positively impact everyone connected to our business. Regular audits, open communication channels, and a zero-tolerance approach to unethical behavior reinforce our commitment to doing the right thing.

Sustainable and Responsible Practices

At Oribay Group Automotive, we are deeply dedicated to sustainability and responsible environmental practices. We have made this a core part of our business strategy, and we strive to minimize our environmental impact and contribute to a healthier planet. Here is how we are making a difference:

- Certified Environmental Management: We have implemented the ISO 14001 standard, ensuring efficient environmental management and adherence to the highest sustainability benchmarks across our operations. This certification provides a framework for us to continuously improve our environmental performance, covering aspects like waste reduction, energy efficiency, and pollution prevention.

- Carbon Footprint Reduction: We are actively engaged in reducing our greenhouse gas emissions. This includes optimizing energy consumption in our facilities, transitioning to renewable energy sources where possible, and investing in energy-efficient technologies. Our ultimate goal is to achieve climate neutrality and contribute to mitigating the impacts of climate change.

- Sustainable Products and Processes: Oribay is dedicated to innovation that prioritizes environmentally friendly materials and technologies. This includes researching and implementing processes that minimize waste, promote recycling, and support a circular economy. We are constantly exploring new ways to make our products more durable, lighter, and easier to recycle, reducing their overall environmental footprint throughout their lifecycle.

Social and Collaborative Environment

We believe that a strong company culture should prioritize both social impact and business success, and at Oribay Group Automotive, we strive to do just that. We actively work to make a positive impact on our communities and foster a culture of cooperation both within our company and beyond

- Social Commitment: We support initiatives that promote the development of local communities. This includes investing in education, training programs, and social welfare projects that contribute to collective progress. We also actively collaborate with organizations dedicated to fostering employment opportunities (Gureak, Hazilan, Red Cross…), helping individuals gain the skills and support they need to succeed in the workforce. As a participant in the UN Global Compact, we align our operations and strategies with ten universally accepted principles in the areas of human rights, labor, environment, and anti-corruption. We believe in empowering individuals and creating opportunities for growth.

- Collaborative Culture: We foster a work environment built on cooperation and teamwork. We encourage cross-departmental interaction and knowledge sharing among our employees to achieve common goals. We believe that diverse perspectives and open communication lead to better solutions and a stronger sense of community.

- Shared Responsibility: Our philosophy is based on the idea that every member of our organization plays a key role in creating social value. We cultivate an inclusive environment where each person feels valued and motivated to contribute to the common good. We believe that a shared sense of responsibility empowers our employees and strengthens our company as a whole.

Resource center

Sustainability

Discover more about our dedication to promoting a greener future and our efforts towards creating a more sustainable mobility industry.

Certifications

We obtain industry-recognized certifications and adhere to the latest standards and regulations, ensuring excellence and meeting expectations.

Careers

Ready to take the next step in your career? Send us your CV, and we will get in touch if a suitable opportunity becomes available.

Our Green Commitment

At Oribay, we focus on developing more sustainable production methods for our solutions

EcoVadis Gold

In 2023, we received the EcoVadis Gold award in recognition of our efforts to enhance sustainability

REACH Compliant

All our adhesives, coatings, and other chemicals are REACH compliant, as we manufacture in Europe

Safer Products

We are committed to finding safer alternatives for health and the environment, such as eliminating PFAS from our products

Renewable Energy

A large part of our production is powered by solar panels, making renewable energy our primary electricity source.

R&D Center

Driving Tomorrow's solutions

At Oribay Group, innovation is part of our DNA. With state-of-the-art laboratory facilities and a team of over 25 scientific and PhD experts specializing in smart chemistry and physics-electronics, we’re well-equipped to tackle the challenges of tomorrow. We’re dedicated to leading the way towards a brighter, more sustainable future through our groundbreaking ideas and technologies.