Plastic and metal parts

Windshield brackets and mounts

ADAS Camera brackets and rearview mirror mounts

We design and manufacture a range of windshield components, including ADAS camera brackets, sensor holders, and mirror buttons, adhering to strict OEM standards for product quality. Partnering with leading windshield manufacturers worldwide, we produce plastic and metal parts in our advanced facilities in Spain. Our focus on precision and quality control ensures that we consistently meet client expectations.

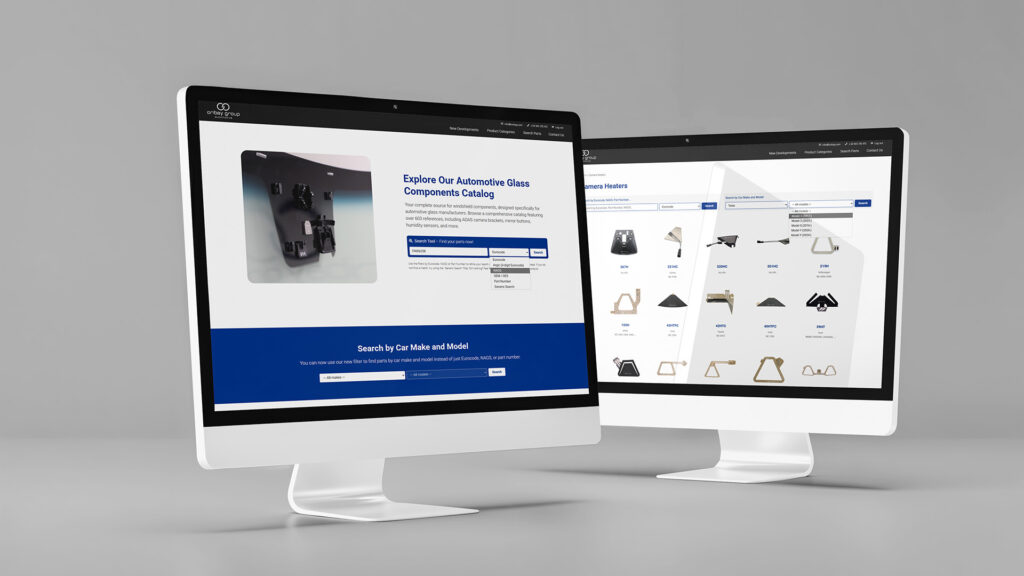

- Online catalog available with EC/NAGS references

- Manufactured in Europe - Spain

- Trusted OEM quality standards

Plastic and metal parts

Made in europe

All our production takes place in Europe, with engineering and manufacturing facilities located in Spain

Engineering Team

Our talented engineers play a crucial role in developing new components and ensuring quality control across our production process.

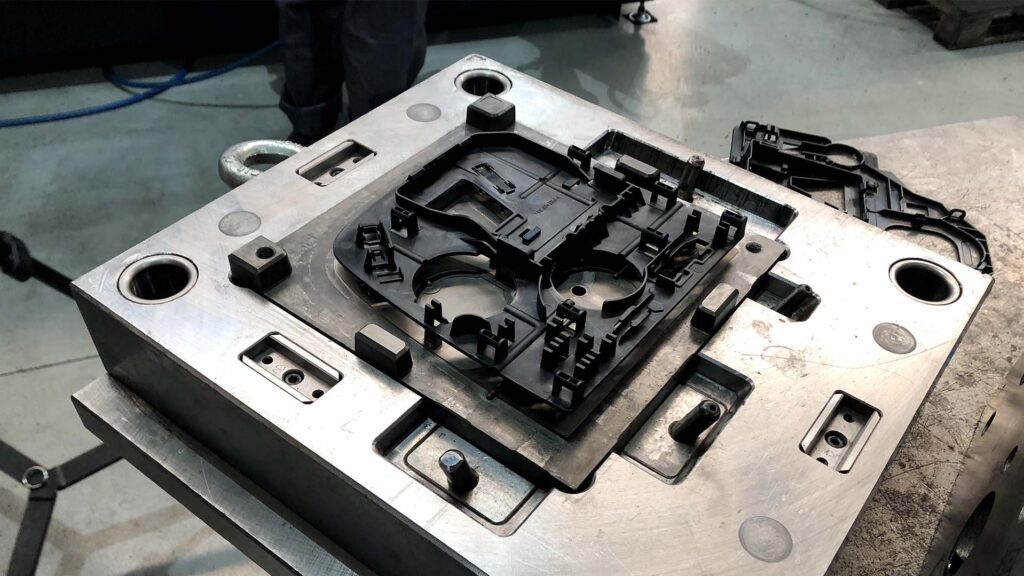

Tooling & Molds

We design and manufacture precision tools in-house, including molds for plastic injection, die-casting, and stamping.

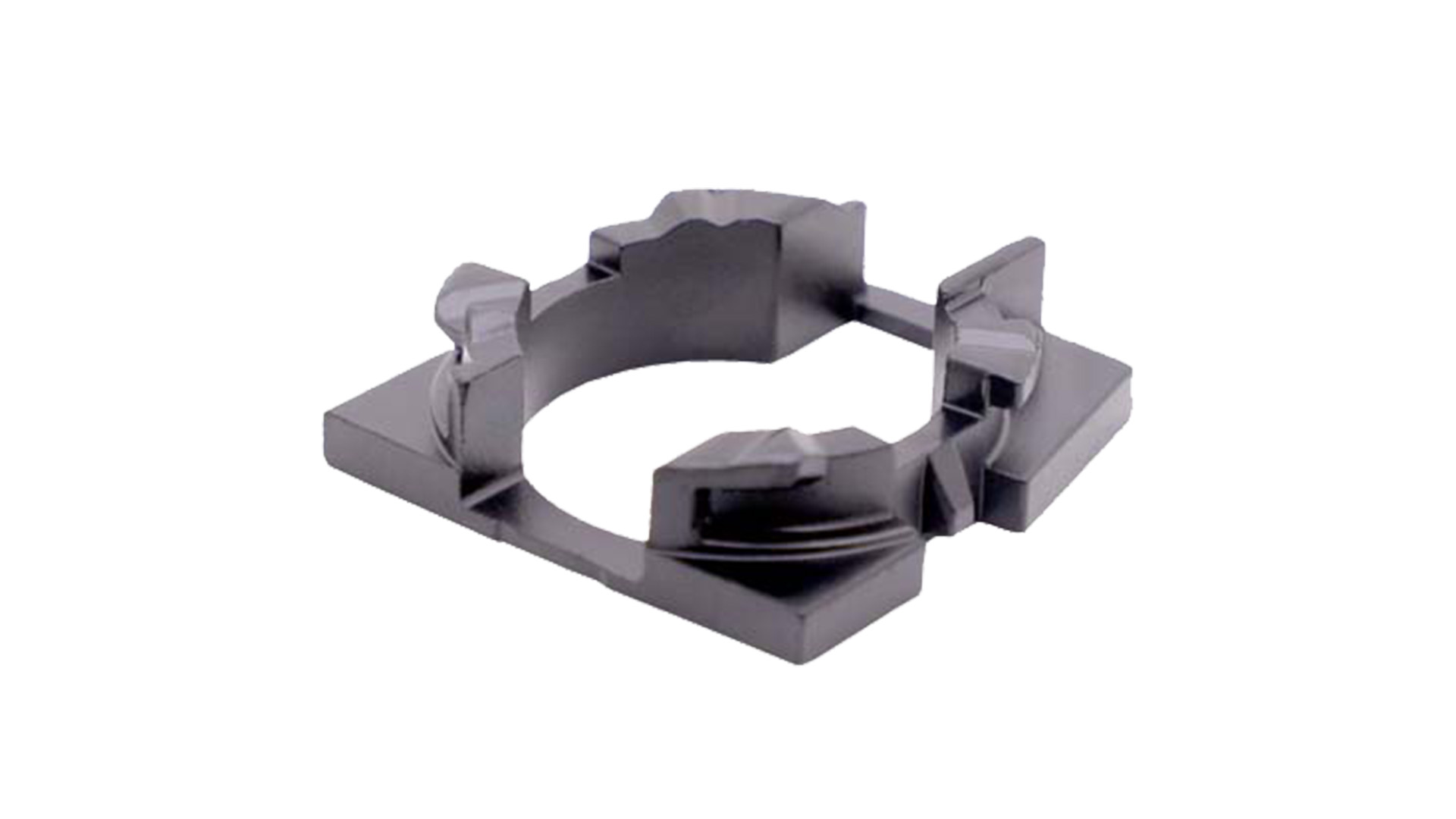

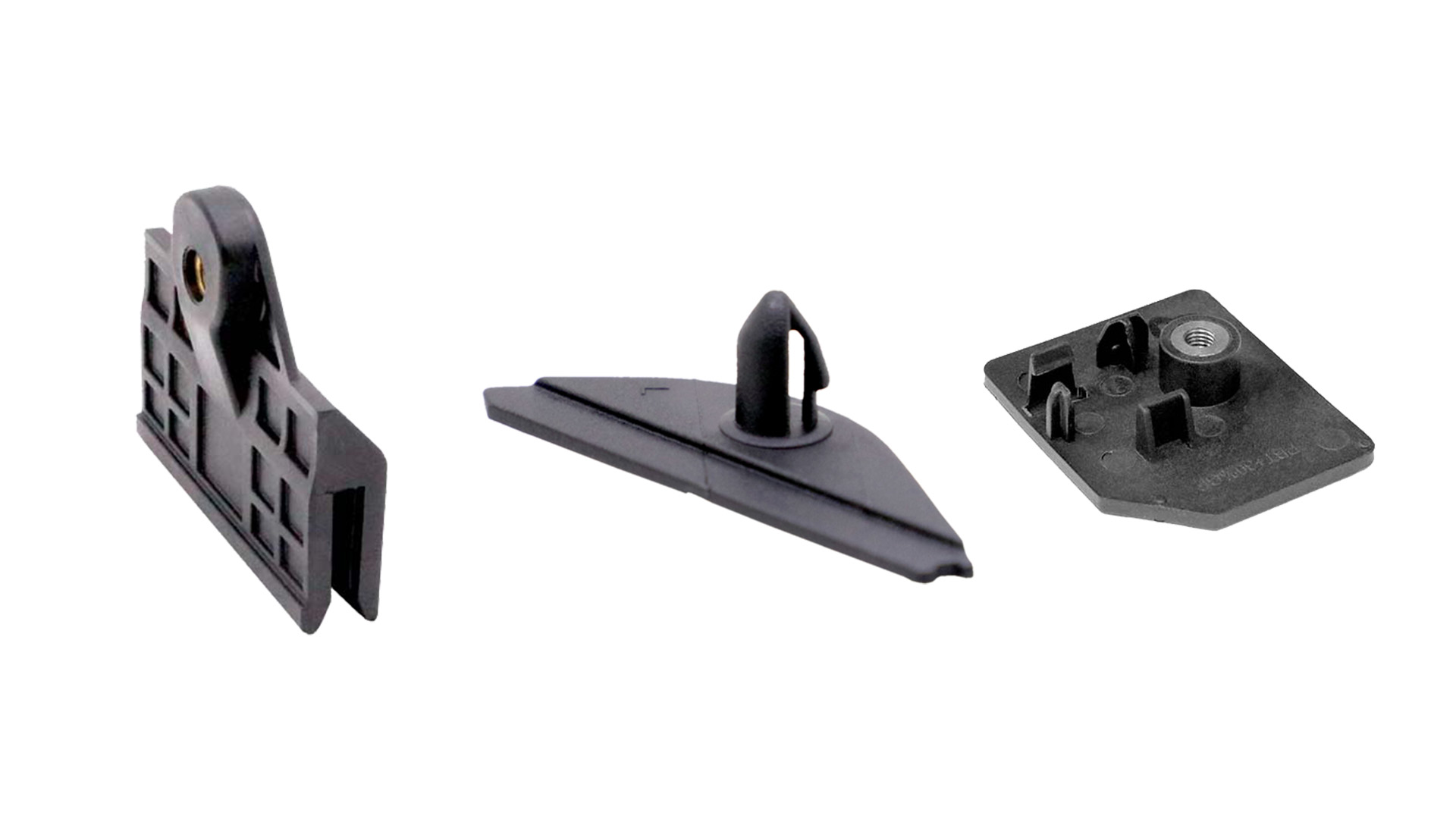

Plastic Injection

We deliver high-quality plastic parts, such as camera brackets and sensor holders, utilizing advanced technology and rigorous quality control measures.

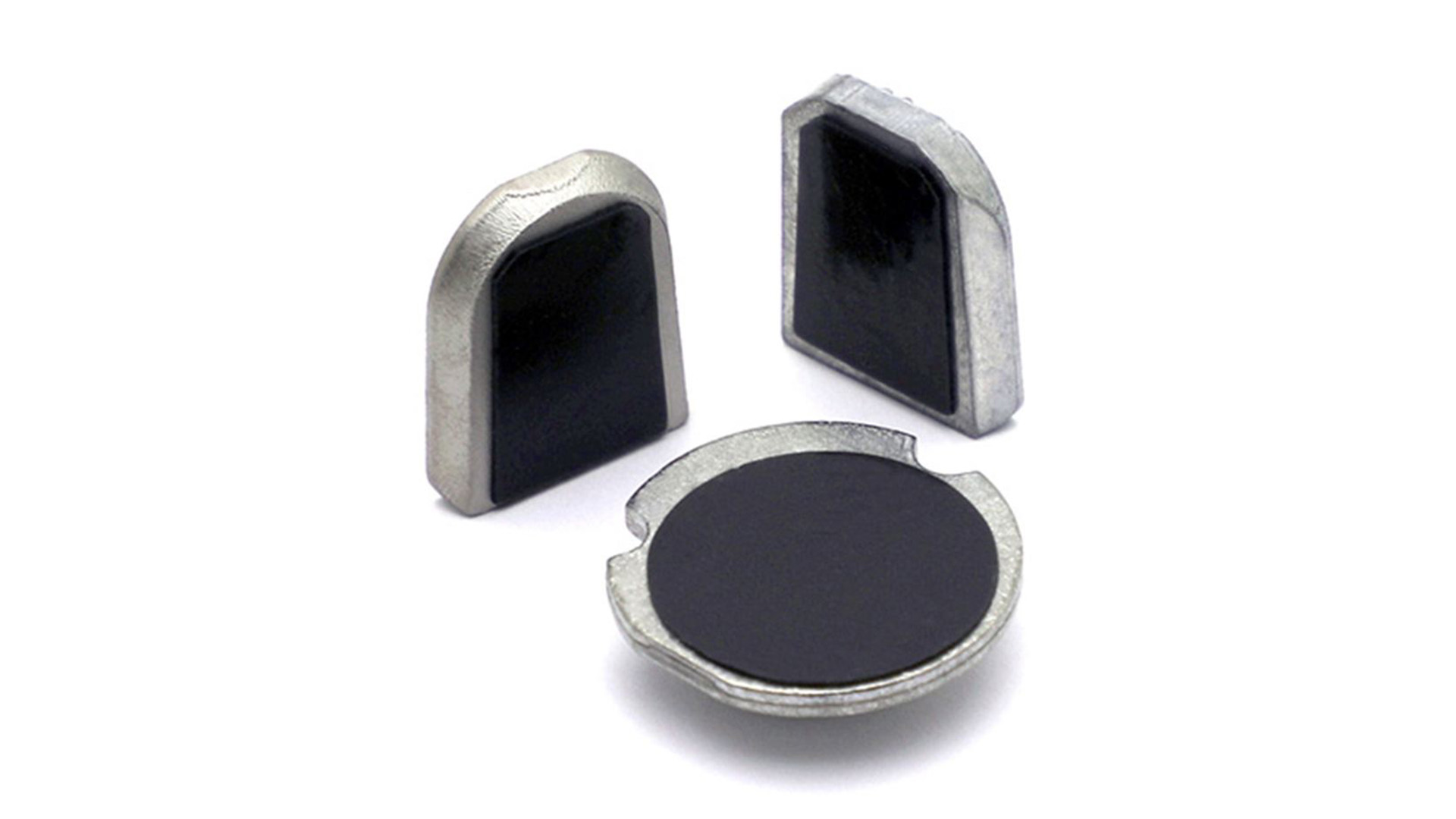

Metal Die Casting

Our state-of-the-art metal die-casting equipment allows us to produce aluminum and zinc alloy components for automotive glass.

Powder Metallurgy

We specialize in producing sintered carbon and stainless steel parts using advanced press equipment (up to 160 tons) and furnaces.

Metal Stamping

We have the expertise and machinery to transform flat metal sheets into specific shapes, enabling us to assemble complex components.

Adhesive Solutions

Windshield Electronics

Windshield Parts Search Tool

- 600+ references available

- NAGS / Eurocode listed

- 2024-25 new developments

What are windshield components?

Windshield components include plastic, metal, and electronic parts that are bonded to the inner upper center of the windshield. Located on the interior side facing the passenger cabin, this area is crucial for various functions, housing items such as ADAS (Advanced Driver Assistance Systems) cameras, sensors, and the rearview mirror mount. These components play a vital role in vehicle safety by supporting technologies for autonomous and assisted driving, as well as ensuring the proper positioning of the rearview mirror. The area is often reinforced to handle the weight and mechanical stresses of the attached components. While these components enhance vehicle safety and functionality, they are typically concealed by a plastic cover that enhances the vehicle’s interior appearance.

Overall, windscreen components are indispensable in modern vehicles, requiring precision engineering for reliable performance, which ultimately contributes to a safer driving experience. At Oribay Group Automotive, we adhere to OEM quality standards and employ the latest engineering and production technologies in-house for the design and manufacture of windshield components.

What is an ADAS camera bracket?

ADAS camera brackets are specialized plastic components that have gained significant importance with the rising adoption of advanced driver assistance systems (ADAS) in modern vehicles. Located on the interior upper central part of the windshield, these brackets are situated behind the plastic cover where the rearview mirror is bonded to the glass. This strategic placement allows them to house essential technologies that enhance vehicle safety and functionality.

The windshield acts as the “eyes” of the car, and the ADAS camera bracket plays a crucial role by supporting advanced driver assistance systems. These systems enable key functions such as adaptive cruise control, lane departure assistance, collision avoidance, and even facilitate autonomous or semi-autonomous driving capabilities in many of today’s vehicles. These ADAS camera brackets serve as multifunctional plates that not only hold the cameras but also accommodate sensors for rain, light, and humidity detection, contributing to a comprehensive driver assistance system.

At Oribay, we focus on designing and manufacturing these components primarily from high-quality plastic. Thanks to our advanced engineering, we can incorporate antireflective surfaces to optimize the camera’s view, ensuring clear and accurate data capture for improved functionality. We are committed to keeping our catalog up to date with the latest windshield camera bracket models. Additionally, we offer advanced adhesion promoter technology to ensure secure bonding of these larger components to the glass using PU adhesives, guaranteeing both durability and performance in a variety of driving conditions.

What is a rearview mirror mount?

A rearview mirror mount, also known as a mirror button, is a critical component that enables the rearview mirror to be securely bonded directly to the windshield glass, rather than being attached to the car’s roof panel. This design has become widely adopted, and nearly all vehicles on the market now use this system to mount their rearview mirrors.

At Oribay, we have been designing and manufacturing these components for over three decades, using various materials such as steel, aluminum, and plastic for both OEM and AGR projects. In addition to producing the mounts, we also manufacture the structural bonding tape commonly used to attach these parts. To simplify the installation process for glass manufacturers, we can apply adhesive tape die-cuts directly onto the mounts, so they only need to be positioned on the windshield and cured in an autoclave oven.

Do you manufacture other windscreen parts? What types?

Yes, we design and manufacture all of our windshield components in-house at our facilities across Europe. Our production plants are located in Spain, specifically in San Sebastian, Pamplona, and Mendaro.

At our facilities, we have the capability to manufacture a wide range of components, including plastic parts through injection molding, metal components via die casting, sintering, and stamping, as well as assembly processes. We also produce electronics, silicones, adhesives, and coatings in our dedicated chemical plant. This comprehensive in-house production allows us to maintain full control over the entire manufacturing process.

Unlike many other suppliers of automotive glass components, this level of control gives us a significant advantage. It allows us to closely monitor every step of production, ensuring the highest quality across all aspects of our solutions. This control also provides us with greater flexibility and faster lead times, enabling us to develop and deliver new components that meet the demands of the latest car models ahead of the competition.

Do you manufacture all your solutions in-house?

We design and manufacture all of our windshield components in-house at our facilities across Europe. Our production plants are located in Spain, specifically in San Sebastian, Pamplona, and Mendaro.

At our facilities, we have the capability to manufacture a wide range of components, including plastic parts through injection molding, metal components via die casting, sintering, and stamping, as well as assembly processes. We also produce electronics, silicones, adhesives, and coatings in our dedicated chemical plant. This comprehensive in-house production allows us to maintain full control over the entire manufacturing process.

Unlike many other suppliers of automotive glass components, this level of control gives us a significant advantage. It allows us to closely monitor every step of production, ensuring the highest quality across all aspects of our solutions. This control also provides us with greater flexibility and faster lead times, enabling us to develop and deliver new components that meet the demands of the latest car models ahead of the competition.

Do you also offer windshield electronic components?

Yes, we do. At our facilities, we design and manufacture a variety of electronic components, including ADAS camera heaters for defrosting and defogging the camera areas. Additionally, we produce defog sensors specifically for Kia and Hyundai windshields, along with connectors and wiring solutions for the windshield region. In addition, we also manufacture sensor silicone pads for both OEM and aftermarket applications, ensuring reliable performance and protection for sensors. We are also involved in several R&D projects focused on developing our own advanced, all-in-one windshield bracket that integrate cameras and sensors, as well as housing solutions for dashcams built into the rearview mirror plastic cover.

Do you work for both OEM and aftermarket projects?

We have deep expertise in both OEM and aftermarket projects. With over three decades of experience, we provide high-quality solutions tailored to the specific needs of each sector. For OEM projects, we work closely with automakers to design and manufacture components that meet the exact specifications and requirements of new vehicle models. We are proud to have all the necessary certifications for automotive OEM, ensuring that our products meet the highest standards of quality and safety. For AGR projects, we offer a wide range of products that ensure compatibility and performance, serving the needs of aftermarket automotive glass manufacturers. Our flexibility and in-depth knowledge enable us to deliver top-notch solutions across both markets.

Do you offer adhesive for the bonding of the parts?

We have our own range of adhesive solutions developed in-house to ensure the highest quality bonding for our parts. For smaller components, such as mirror mounts, we have developed Ori-Tape, a structural bonding adhesive tape that provides strong, permanent bonding to glass. Additionally, we offer advanced adhesion promoters designed for bonding plastic parts, like camera brackets and sensor holders, to the glass using PU adhesives, eliminating the need for toxic primers. We are also in the final stages of developing our own fast-curing adhesive to further enhance the efficiency and performance of our bonding solutions.