Ori-Polar™

Adhesionpromoters

High-Performance Bonding for Plastic and Glass

Ori-Polar™ is a range of surface treatments that have been developed to enhance the bonding of PA/PPA/PBT/PP plastic parts, e-coated metal components, or glass when utilizing polyurethane (PU) adhesives. These promoters improve the adhesion properties of the material by generating chemical functional groups that enhance the compatibility of the part with the adhesive employed. Ori-Polar™ is a safe and environmentally friendly choice, as it does not contain any harmful chemicals, unlike the conventional primers.

- Toxic-free alternative to primers

- Compatible with PU and SBT adhesives

- Up to 1 year of storage life

Toxic-free alternative to primers

Ori-Polar™ range of solutions

Ori-Polar™ OPL21

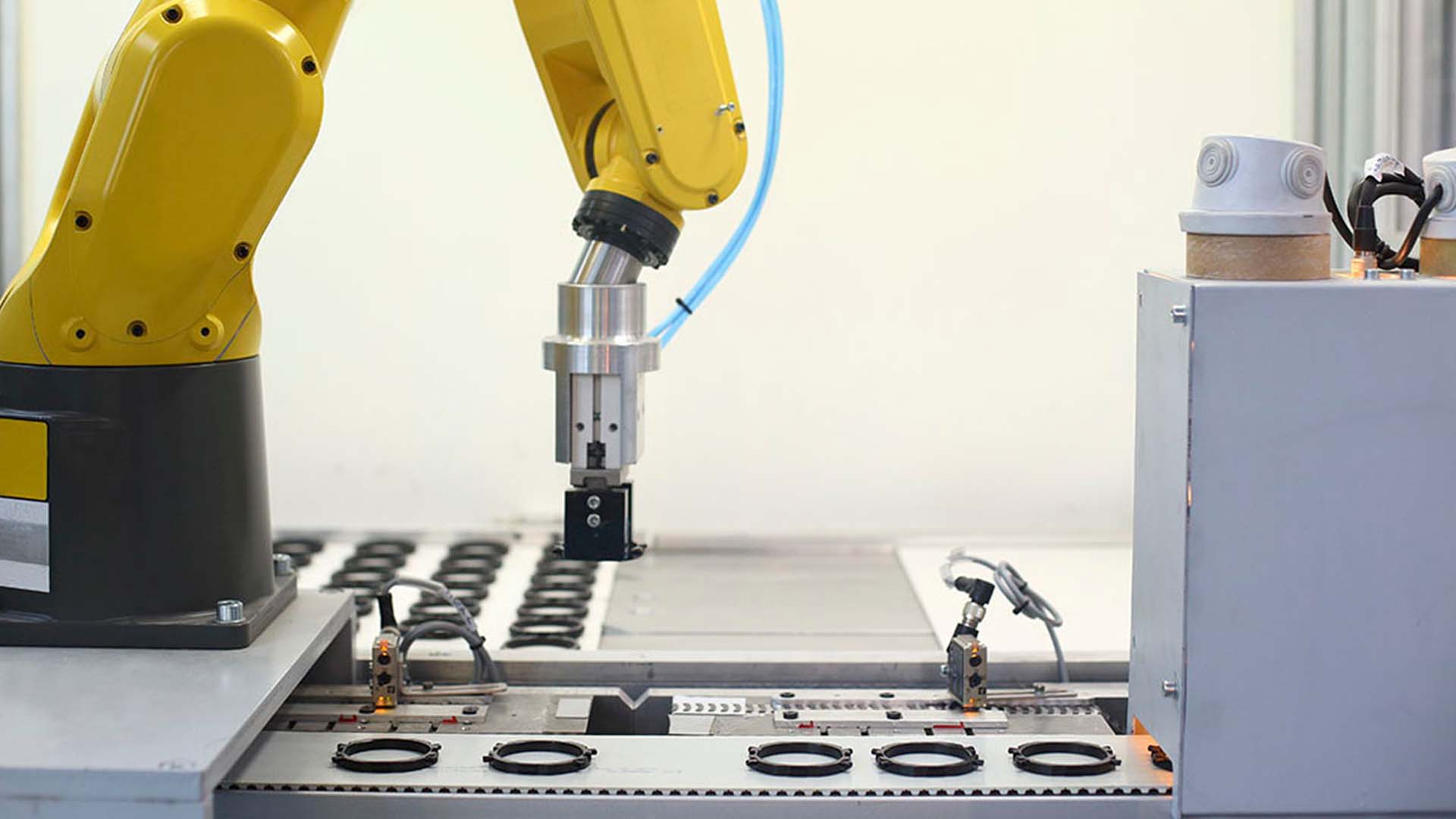

- Part spray + UV curing

- Plastic (PA/PPA) and e-coatings

Ori-Polar™ OPL26

- Glass spray + UV curing

- Glass surfaces (windshield)

Ori-Polar™ OPM11

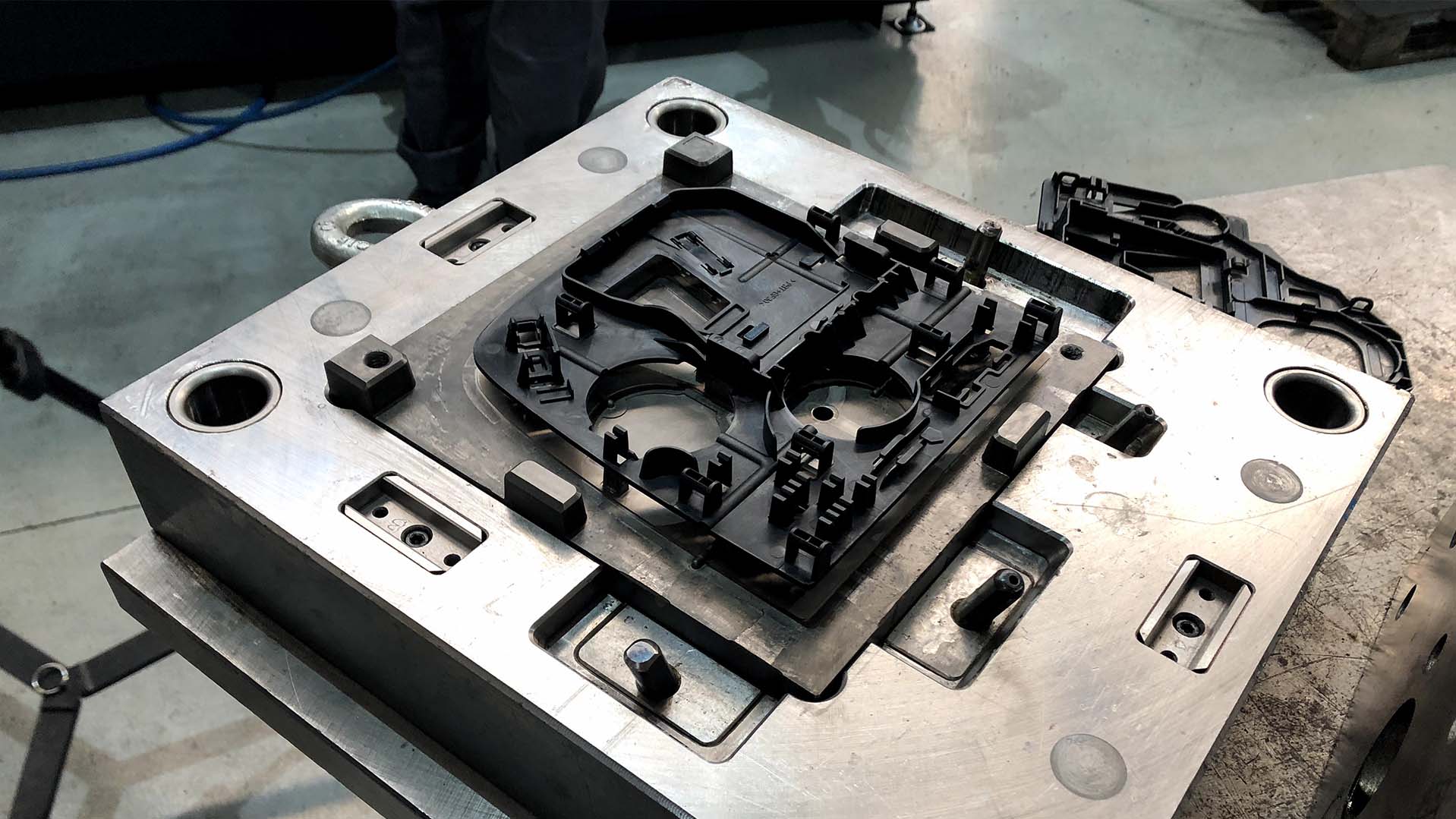

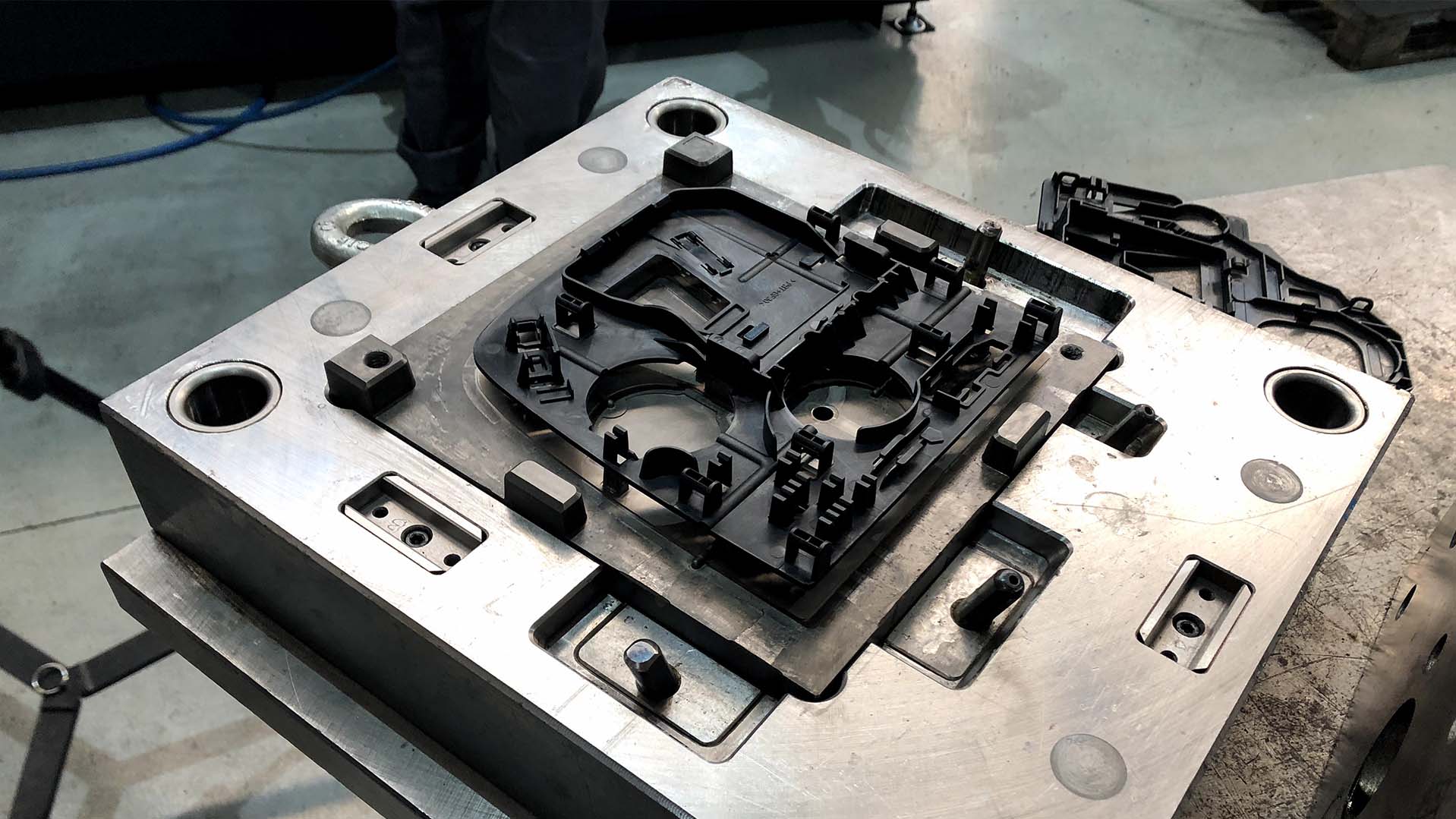

- In-mold application

- Plastic parts (PBT/PA/PPA/PP)

Made in europe

R&D Department

Our adhesive solutions are developed in-house, powered by the latest technology and innovative processes in our laboratories.

Adhesive Production

We also have access to state-of-the-art chemical production facilities, enabling us to manufacture our range of adhesives at large scale.

Adhesive Converting

We offer a comprehensive service by converting and applying our adhesive solutions to the windshield components we manufacture.

Why Choose Ori-Polar™

No More Toxic Primer

Long Storage Life

Components treated with Ori-Polar™ can be stored for up to one year before bonding with PU adhesives. This offers a significant advantage, as there is no need for immediate bonding after treatment. The parts can be shipped and stored without the need for special climate conditions, providing greater flexibility in logistics and inventory management.

Simplified Bonding Process

In-mold Application

What is Ori-Polar™ adhesion promoter?

Ori-Polar™ is a range of advanced and toxic-free adhesion promoters designed to improve the bonding between plastic, epoxy-coated metal, or glass surfaces and polyurethane (PU) liquid adhesives. There are different solutions available depending on the material to be coated and the specific process used. This solution works by introducing chemical functional groups that enhance the material’s compatibility with the adhesive, allowing the PU adhesive to better wet and adhere to the surface. The result is a stronger, more durable bond between the substrate and the adhesive.

Can Ori-Polar™ be used with other types of adhesives?

What is the shelf life of this adhesion promoter?

What are the differences between OPL21, OPM11, and OPL26?

OPL21, OPM11, and OPL26 are specialized formulations of Ori-Polar™ adhesion promoters, each designed for different materials and processes to optimize adhesion performance.

OPL21: This treatment involves spraying the adhesion promoter onto the plastic or e-coated part, followed by UV curing. It can be applied directly after part manufacturing at our facilities. OPL21 is ideal for plastic parts that require enhanced bonding properties before applying PU adhesives, providing a strong and durable bond.

OPM11: An innovative, patent-pending solution, OPM11 is applied directly in-mold during the plastic injection process. It requires no additional curing, making it a highly efficient solution that streamlines production by eliminating extra steps. This solution is perfect for plastic parts that need enhanced adhesion without post-manufacturing processes.

OPL26: Similar to OPL21, OPL26 involves spraying the adhesion promoter, but it is specifically applied to the glass side of the component, followed by UV curing. This solution is designed to optimize the bonding between glass surfaces and PU adhesives, providing excellent adhesion properties for glass components.

Each product is tailored to meet the unique requirements of the material being treated and the production process, ensuring optimal adhesion and efficiency for a range of applications.

What are the key benefits of Ori-Polar™ compared to traditional primers?

Ori-Polar™ offers several key advantages over traditional, toxic primers, making it a more efficient and safer solution for enhancing adhesion:

Non-toxic: Unlike conventional primers, Ori-Polar™ is free from carcinogenic isocyanates, ensuring a safer working environment. Additionally, the use of Personal Protective Equipment (PPE) is not required when using Ori-Polar™, unlike with traditional primers, which pose health risks to workers.

Long storage life: Parts treated with Ori-Polar™ can be stored for up to one year before bonding with PU adhesive. In contrast, traditional primers must be applied immediately before PU adhesive application, limiting flexibility in production scheduling.

Simplified process: Ori-Polar™ treatments like OPL21 and OPM11 can be applied directly at Oribay Group manufacturing facilities, whereas traditional primers require application at the auto glass factory, adding complexity and time to the process.

In-mold application: OPM11 is applied directly during the plastic injection molding process, offering an innovative in-mold solution that enhances manufacturing efficiency and eliminates the need for additional steps like post-treatment curing.

Overall, Ori-Polar™ simplifies the adhesion process while offering a safer, more flexible, and more efficient alternative to traditional primers.