Structuralbonding tape

Best-in-class adhesion strength and handling

Ori-Tape™ SBT is the ultimate structural adhesive tape for bonding plastic and metal windshield components to glass, including mirror buttons and sensor holders. This bonding tape combines the strength of structural adhesives with the handling ease of pressure-sensitive tapes. Before curing, it offers convenient handling properties, making it easy to work with. Once heat-cured, Ori-Tape™ transforms into a robust structural adhesive, providing exceptional strength and long-lasting bonding.

- Strong structural bonding capability

- Easy-to-handle SBT adhesive

- Up to 1 year shelf life

Optimized Bonding with Ori-Tape™

Ori-Tape™ is a cutting-edge structural adhesive specifically designed in-house by our team of experts, leveraging years of experience in bonding components to glass. This unique structural bonding tape is engineered to meet the precise demands of OEM automotive applications, ensuring a strong, reliable bond to the glass. What sets Ori-Tape™ apart is its exclusive formulation, making it the only adhesive on the market tailored to optimize the performance of mirror buttons and other components bonded to glass.

Why Choose Ori-Tape™

Discover the key benefits of Ori-Tape™, including efficient shipping, extended shelf life, and superior bonding performance

No Refrigeration Needed

Ori-Tape™ eliminates the need for refrigerated shipping and styrofoam boxes, reducing costs and simplifying logistics. It maintains full performance for up to a year at 10°C (50°F) or six months at 27°C (80.6°F), ensuring easy storage and hassle-free transport.

Up to 1-Year Shelf Life

Converting and Application

Flexible Supply Options

High Bonding Strength

Made in europe

R&D Department

Our adhesive solutions are developed in-house, powered by the latest technology and innovative processes in our laboratories.

Adhesive Production

We also have access to state-of-the-art chemical production facilities, enabling us to manufacture our range of adhesives at large scale.

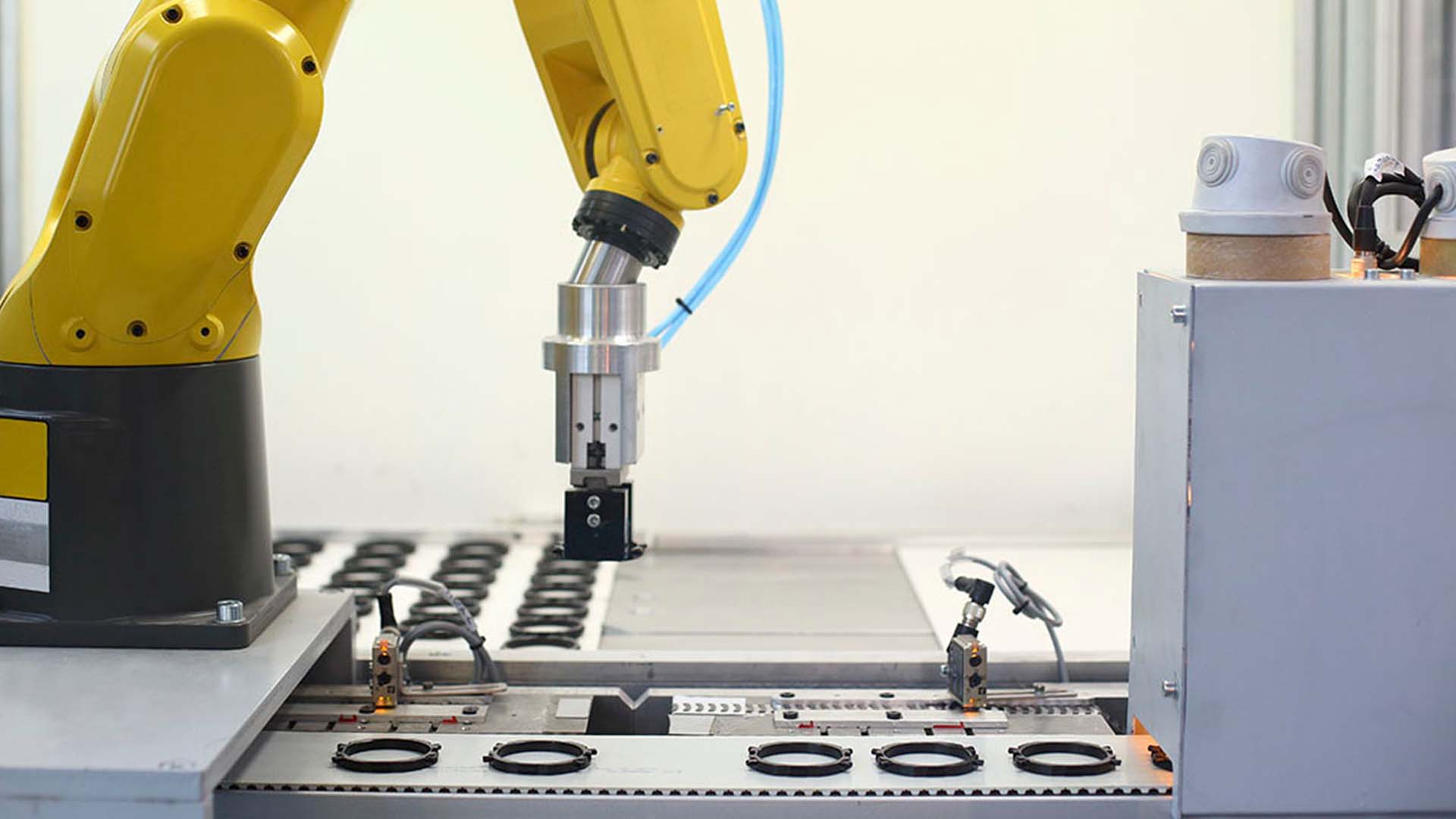

Adhesive Converting

We offer a comprehensive service by converting and applying our adhesive solutions to the windshield components we manufacture.

What is Ori-Tape™ and how strong is its bond?

Ori-Tape™ is a high-performance structural bonding tape (SBT) specifically designed for the permanent bonding of windshield parts to the glass on the inner side of the car cabin. It delivers strong, reliable bonds while remaining easy to handle before curing. With more than 30 years of expertise in the windshield component industry, we developed this adhesive to meet the demanding needs of bonding parts like rearview mirror mounts and rain sensor holders to windshield glass.

Once cured, Ori-Tape™ creates a robust, long-lasting bond that meets all OEM standards and has been thoroughly tested through extensive R&D. With superior weather resistance, it ensures the bond stays strong over time, making it perfect for automotive applications. The adhesive reaches its full strength when activated by heat — either 140 °C (284 °F) for 20 minutes or 130 °C (266 °F) for 25 minutes in an autoclave — ensuring the highest level of safety, stability, and performance.

Why choose Ori-Tape™ over other SBT adhesives?

There is no other adhesive on the market that is as specifically tailored for this use. Ori-Tape™ outperforms other SBT adhesives with a significantly longer shelf life and the added convenience of not requiring refrigerated transport, making it both cost-effective and easy to handle. Its exceptional mechanical and chemical properties ensure superior durability and resistance to a wide range of conditions. Unlike many competitors, Ori-Tape™ minimizes stress on the glass both during and after curing, offering a reliable, long-lasting bond.

In addition to its performance, Ori-Tape™ provides flexible service, optimized die-cuts, and consistent quality control through in-house production. You’ll also benefit from comprehensive engineering support and strict quality assurance, ensuring the highest reliability and peace of mind.

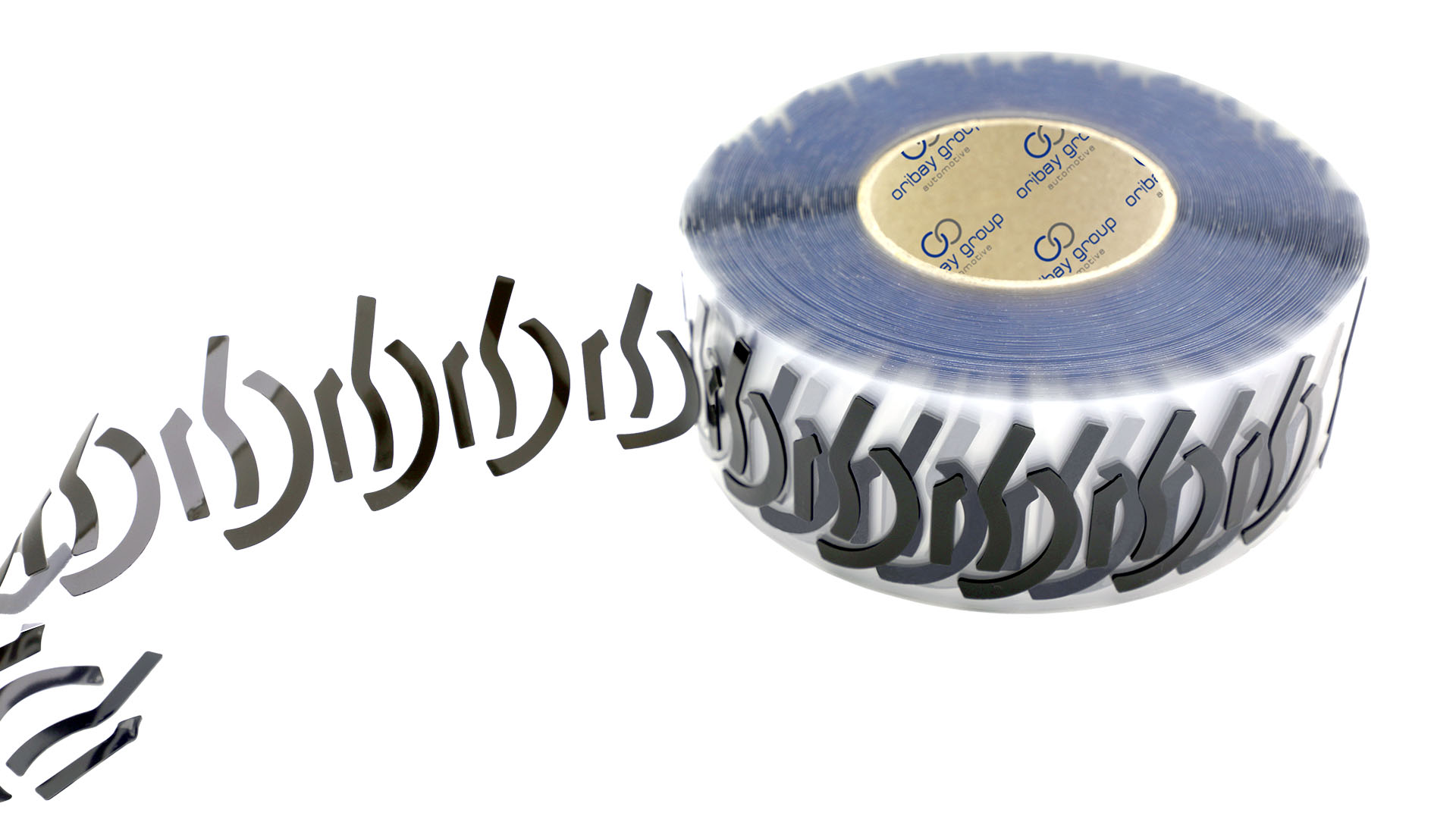

What supply options are available for Ori-Tape™?

We offer two convenient supply options for Ori-Tape™:

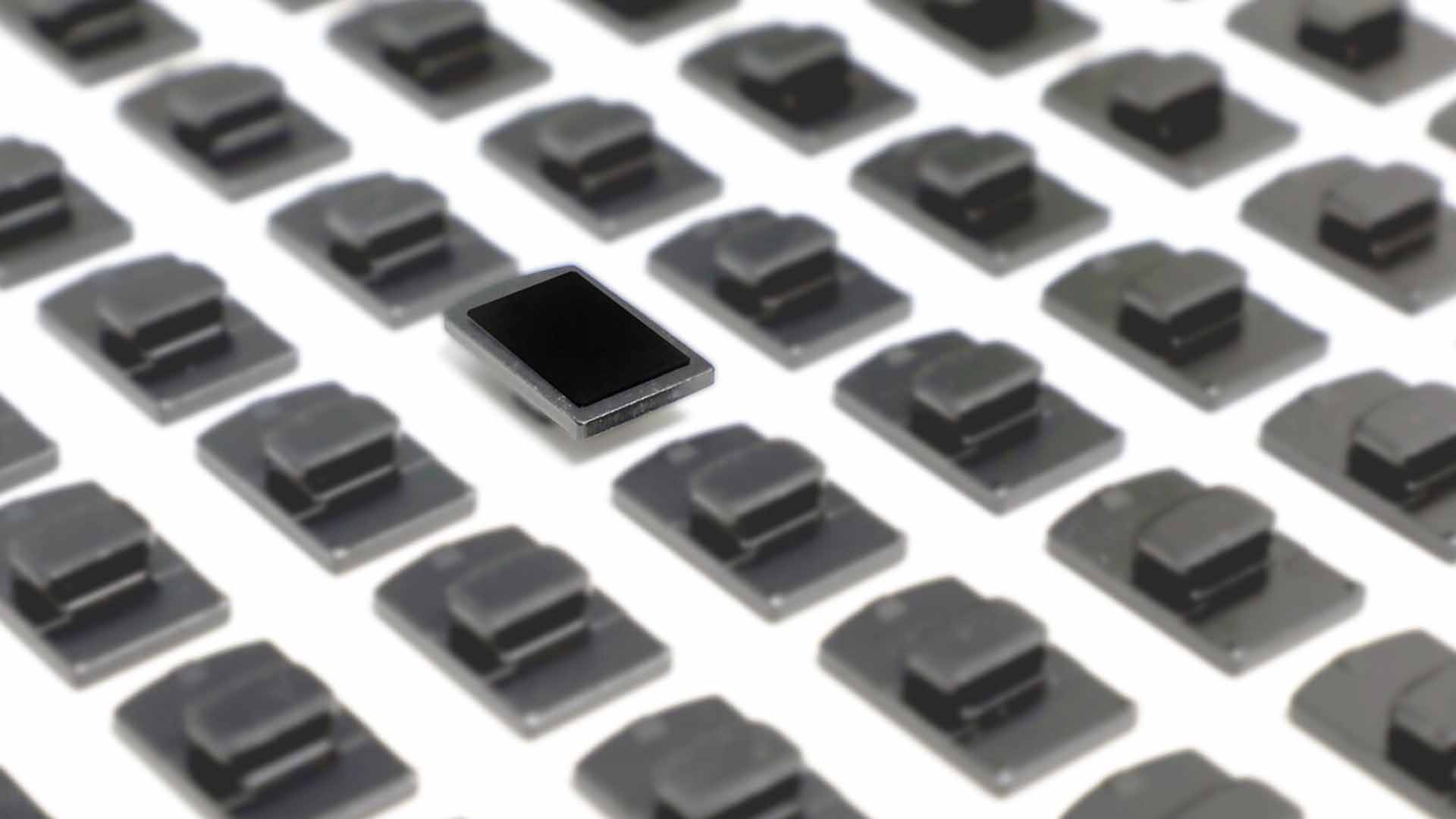

a) Parts with Tape: In this option, we apply the Ori-Tape™ die-cuts to the windshield parts before shipping them to you in cardboard trays or reels. This allows for quick and easy installation, as the tape is already applied, eliminating the need for you to handle the application.

b) Die-cuts on Liners: With this option, we ship the custom die-cuts of Ori-Tape™ on plastic or paper liners directly to your manufacturing plant. This provides you with the flexibility to apply the tape yourself.

In both options, we rely on the latest in-house adhesive converting and application robotic technologies to ensure precision, consistency, and flawless execution of the process.